Description

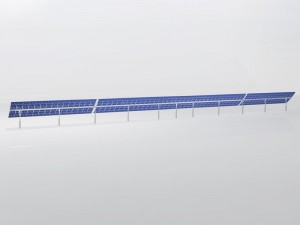

* Simple structure, easy maintenance and installation, designed to be applicable to a variety of complex terrain

* Flexible photovoltaic support structure will be more suitable for various large-span application sites such as ordinary mountains, barren slopes, ponds, fishing ponds, and forests, without affecting crop cultivation and fish farming;

* Strong wind resistance. The flexible photovoltaic support structure, component system, and specialized component connectors have passed wind tunnel tests conducted by the China Aerospace Aerodynamic Technology Research Institute (anti super typhoon level 16);

* Photovoltaic support structure uses four installation methods: hanging, pulling, hanging, and supporting. * Flexible photovoltaic support structure can be freely erected in all directions, including up, down, left, and right, effectively improving the support method of distributed photovoltaic power generation systems;

* Compared with traditional steel structure schemes, flexible photovoltaic support structure have less usage, less load-bearing capacity, and lower cost, which will greatly shorten the overall construction period;

* Flexible photovoltaic support structure have low requirements for site foundation and strong pre-installation capability.

|

Flexible support |

|

|

Components Installation |

|

| Compatibility | Compatible with all PV modules |

| Voltage level | 1000VDC or 1500VDC |

|

Mechanical Parameters |

|

| Corrosion-proofing Grade | Up to C4 corrosion-proof design(Optional) |

| Inclination angle of component installation | 30° |

| Off-ground height of components | > 4 m |

| Row spacing of components | 2.4m |

| East-west span | 15-30m |

| Number of continuous spans | > 3 |

| Number of piles | 7(Single group) |

| Foundation | Cement or static pressure pile foundation |

| Default wind pressure | 0.55N/m |

| Default snow pressure | 0.25N/m² |

| Reference standard | GB50797,GB50017 |

-

Adjustable Series, Wide Angle Adjustment Range,...

-

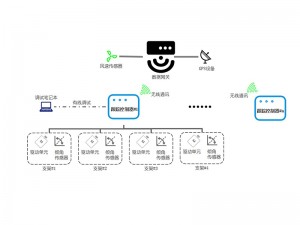

Economical Control System, Less Ebos Cost, Four...

-

Description Of Distributed Generation Solar Pro...

-

Profession Engineer Provides Customized Solutio...

-

Efficient Supply For Projects

-

Multi Drive Flat Single Axis Tracker